The Role of CAD and CAM in Modern Manufacturing

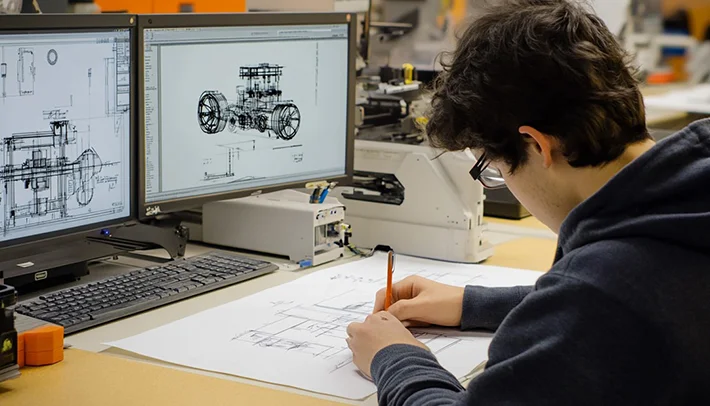

Think of trying to construct a complicated machine such as an engine or an advanced piece of electronics using simply a pencil and paper. Just how would one make sure all components meshed well or worked in a way that this particular construct could be feasible?

This remained a reality in manufacturing for a very long time. However, our current reality is an era where design and manufacturing have become an integrated whole because of digital technology. At the core of this revolution are two interlinked principles: Computer Aided Design and Computer Aided Manufacturing. Computer Aided Design and Computer Aided Manufacturing are not just computer software programs but represent a basic language by which human ingenuity expresses itself in making reality out of imaginative ideas.

The Architect of Digital Form: CAD

A CAD system is an electronic graphic working table. Here, designs can be generated, edited, evaluated, and optimized before a single piece of material is cut. CAD replaces conventional blueprints with three-dimensional graphic models, which are accurate to a micron.

The strength in a CAD system is in its capacity to model a real-world situation. The engineer can check a part for strength, examine it for thermal stress, and in some systems, observe how a complicated mechanism will function, all within a digital model. Such an efficient developmental stage saves on costly prototypes and accelerates the whole life cycle. CAD verifies that a finalized design is sound and serves a purpose when it is finalized.

⦿ Precision: Makes sure all dimensions and angles are precise.

⦿ Visualisation: Enables viewing of any angle of the product.

⦿ Simulation: It is used to forecast performance under varying situations.

The Digital Maestro: CAM

While CAD is considered to be "the mind" behind designing an object, CAM can be referred to as "the hand" which leads to the creation of a product. A CAM application takes a final digital model developed in CAD and converts this model into a format which can be processed by computer-controlled machine tools.

The function of CAM is to find an efficient and effective way to machine a part. It determines where the machine tools will go, how fast the material will be cut away, and in what order these operations will take place. The output of a CAM system is called numerical control code, which is a set of instructions given directly to a machine. The combination of design and production capabilities in a computer gives a machine a capability to produce a complex part at a speed as well as an accuracy never before possible.

The Partnership of Progress

The actual benefit of CAD and CAM technology is in their integration. Such seamless digital threads have become a hallmark of efficient production in the current manufacturing paradigm. With this technology, designers can immediately transmit designs to a production facility.

Such integration leads to a reduction in production cost, increased product reliability, and a quick response to market requirements, with a speed and agility which is unprecedented in history. As you go from an aircraft wing to a smartphone case, this CAD-CAM integration is an invisible integrating factor to the world of materials.